The Microchannel Heat Exchanger Market Outlook emphasizes the growing demand for compact, efficient, and high-performance thermal management solutions. As Per Market Research Future, microchannel heat exchangers (MCHEs) are widely used in automotive, HVAC, refrigeration, chemical, and power generation industries due to their superior heat transfer efficiency, reduced size, and lower refrigerant usage compared to traditional heat exchangers.

Market Dynamics

The growth of the Microchannel Heat Exchanger Market Outlook is driven by rising energy efficiency requirements, technological advancements, and the increasing demand for lightweight and compact thermal management solutions. MCHEs offer benefits such as high heat transfer rates, reduced pressure drop, corrosion resistance, and environmental sustainability due to lower refrigerant consumption.

Technological developments, including advanced manufacturing processes, corrosion-resistant coatings, and multi-stream designs, improve performance, durability, and reliability. Additionally, growing environmental regulations and energy efficiency mandates are encouraging industries to adopt advanced microchannel heat exchanger solutions for sustainable operations.

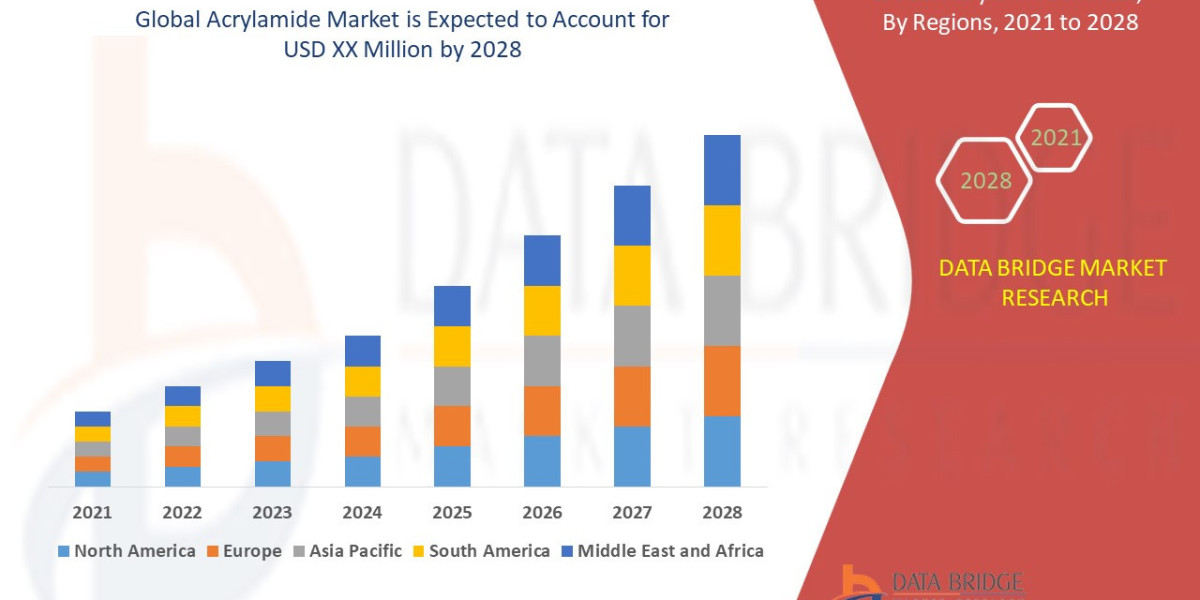

Regional Insights

North America holds a significant market share due to the presence of a mature automotive and HVAC industry, advanced research infrastructure, and high adoption of energy-efficient systems. The United States and Canada are leveraging MCHE technology to optimize vehicle cooling systems, refrigeration, and industrial thermal management.

Europe shows steady growth driven by stringent energy efficiency standards, renewable energy integration, and investments in advanced HVAC and refrigeration technologies. Countries like Germany, France, and the UK are implementing MCHEs to enhance performance, reduce energy consumption, and support sustainable operations.

Asia-Pacific is emerging as a high-growth region due to rapid industrialization, increasing automotive production, and growing demand for energy-efficient cooling solutions. China, India, Japan, and South Korea are key contributors, investing heavily in automotive, chemical, and power generation applications that rely on compact and efficient thermal management systems.

Market Segmentation

The microchannel heat exchanger market can be segmented based on type, application, and material. Types include parallel flow, cross-flow, and multi-pass MCHEs. Parallel flow designs provide compact solutions for automotive and HVAC applications, while cross-flow and multi-pass designs are preferred in industrial and power generation settings for enhanced heat transfer efficiency.

Applications include automotive radiators, HVAC systems, refrigeration units, chemical processing, and power generation. Materials such as aluminum, stainless steel, and copper enhance thermal conductivity, corrosion resistance, and durability. Segmenting the market allows manufacturers to deliver tailored solutions that meet specific operational and environmental requirements.

Industry Trends

Key trends shaping the Microchannel Heat Exchanger Market Outlook include:

Automotive Industry Adoption: Increasing use of MCHEs in vehicle radiators and air-conditioning systems for fuel efficiency and lightweight design.

Energy Efficiency and Sustainability: Growing emphasis on reducing refrigerant usage, energy consumption, and carbon footprint drives adoption of advanced MCHE solutions.

Advanced Manufacturing Techniques: Techniques such as brazing, extrusion, and multi-layer channel fabrication improve heat transfer efficiency, reliability, and compactness.

These trends highlight the focus on efficiency, compact design, and sustainable thermal management across diverse industries.

Challenges

Despite significant growth potential, the microchannel heat exchanger market faces challenges such as high manufacturing costs, complexity in fabrication, and susceptibility to clogging in certain applications. Designing MCHEs for harsh industrial environments, high-pressure applications, or fluids containing particulates requires advanced engineering and material selection.

Additionally, maintenance and cleaning can be challenging due to narrow channels and compact design. Manufacturers must focus on innovation, corrosion resistance, and optimized designs to ensure long-term reliability and performance under diverse operating conditions.

Future Outlook

As Per Market Research Future, the microchannel heat exchanger market is expected to grow steadily due to the increasing adoption of energy-efficient thermal management solutions, automotive growth, and rising industrial and HVAC applications. Future developments will likely focus on high-performance materials, multi-stream and multi-pass designs, and integration with smart systems for optimized thermal control.

Emerging applications include electric vehicles, renewable energy systems, industrial process cooling, and compact refrigeration systems. Continuous advancements in design, manufacturing, and material science will drive market adoption while supporting sustainable, energy-efficient, and high-performance thermal management solutions globally.

Key Players

Prominent companies in the microchannel heat exchanger market include Modine Manufacturing Company, Daikin Industries Ltd., Mahle GmbH, Denso Corporation, and Hanon Systems. These companies focus on technological innovation, global expansion, and providing high-performance, energy-efficient, and durable MCHE solutions for various industrial and commercial applications.

FAQ

Q1: What is a microchannel heat exchanger?

A1: A microchannel heat exchanger is a compact, high-efficiency device used to transfer heat between fluids in automotive, HVAC, refrigeration, and industrial applications.

Q2: Where are microchannel heat exchangers used?

A2: They are used in vehicle radiators, HVAC systems, refrigeration units, chemical processing, power generation, and industrial cooling applications.

Q3: What drives the microchannel heat exchanger market?

A3: Market growth is fueled by energy efficiency requirements, compact design demand, environmental regulations, automotive growth, and industrial cooling needs.

More Related Reports:

Submersible Pumps For Mining Sector Market